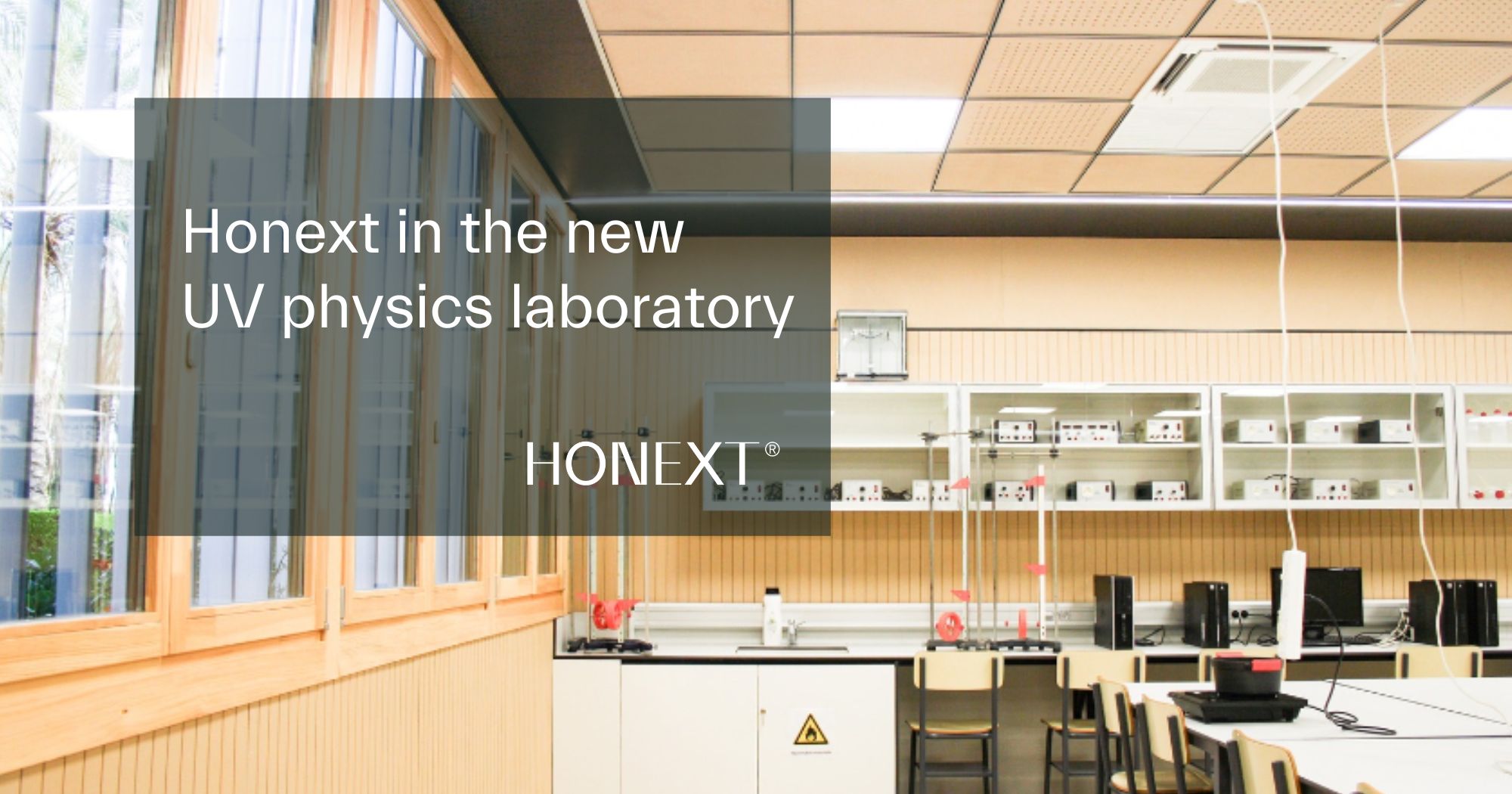

The University of Valencia has presented the remodelling of its General Physics laboratory, a project managed and directed by the Servei Tècnic i de Manteniment (hereinafter STM) of the University of Valencia under the auspices and leadership of the Vicerectorat d’Economia i Infraestructures de la Universitat.

Health and sustainability: The main objectives that have been sought in this reform have been aimed at maximising the comfort and health of its users, while respecting the environment.

The work was received on 10 September 2024 in the presence of, among others, the Vice-Rector for Economics and Infrastructures, Justo Herrera, the Dean of the Faculty of Physics, Enric Valor, accompanied by the STM technicians responsible for the project, Samuel Ballester, architect and responsible for the design and execution of the work, María Dolores Yagüe, technical architect and responsible for execution and Cristina Mateo, Director of the Technical and Maintenance Service. Also present were technicians and management staff of the Faculty, the designer, Julio Mascaró and the construction company, Consval 2012, S.L.

The renovation uses circular and healthy materials such as Honext, which is used in the wall cladding and ceilings, where panels have been installed, providing warmth and comfort as well as optimum acoustic insulation. In addition, they have been installed on a 6 cm cork base, enhancing their insulating effectiveness.

To protect the surfaces, the panels have been treated with Sikkens (Akzonobel) brand water-based varnish, respecting the healthiness and recyclability of the material and thus contributing to the generation of a safe and healthy interior.

Honext boards are Cradle to Cradle Certified® Gold C2C Certified® and Material Health Certificate™ Gold Level certified, proving their circularity and safety for indoor use.

They are made from residual cellulose fibres from the paper industry, a waste that is destined for landfill or incineration and that thanks to the biotechnological process patented by Honext can be converted into these boards that have different applications in interior use and have a positive impact on the environment.

Positive impact of using HONEXT:

315m2 used = 2268Kg of waste rescued = 2517 Kg/CO2 rescued.

Health and sustainability: Attention to detail for the maximum reduction of energy consumption.

The reduction of energy consumption has been present in every choice of the remodelling of the laboratory in line with the commitment of the University of Valencia in the fight against climate change.

Recently, the University of Valencia (UV) improved its position in THE University Impact Rankings, an international ranking that measures the performance of universities in achieving the Sustainable Development Goals (SDGs) of the United Nations. UV is ranked in all 17 goals and is number 27 in goal 13 (take urgent action to combat climate change and its impacts).

The laboratory has large windows in order to take advantage of natural light and therefore the incorporation of low-emissivity solar glass has been taken into account to avoid temperature exchange with the outside. Wooden windows have also been chosen, a natural material that captures CO2 and contributes to the comfortable and warm atmosphere of the room.

To control solar radiation, the exterior of the building is protected by louvres that function as blinds, allowing light to enter and protecting from solar radiation as appropriate.

Likewise, air renewal is carried out by means of a heat recuperator, installed in an area adjacent to the laboratory, which allows the interior temperature to be maintained by regenerating the air, which works autonomously and facilitates the management of the ventilation of the space, guaranteeing a warm environment free of impurities at all times.

All these elements result in a drastic reduction in the use of heating and air conditioning.

The laboratory has LED lighting to further optimise the energy consumption of the space.

All in all, the energy efficiency of the laboratory is remarkable, scoring 2.1 in airtightness tests, Passivhaus Certification.

The design principles used in the refurbishment of the General Physics laboratory were based on the five key principles of Passivhaus design, which are:

– Passivhaus windows, either as certified windows or windows that are not certified but installed with maximum airtightness criteria and manufactured with maximum thermal insulation materials. In the case of the laboratory, windows with wooden frames, triple glazing and low-emissivity solar glass.

– Adequate ventilation strategy. In the Passivhaus design, there is a constant supply of fresh air through the ventilation system. In this sense, the laboratory has a heat exchanger that guarantees the supply of air to the rooms almost at room temperature, without the need for supplementary heating (the cold and heat remain outside).

– Thermal insulation. Thanks to good thermal insulation, the space retains heat in winter and avoids it in summer. In the laboratory this has been achieved thanks to a 6 cm base of natural cork.

– Airtightness. In a Passivhaus design there is a continuous hermetic layer, which protects the structure, prevents energy losses and improves comfort. In this renovation, this has been achieved with a layer of plaster, airtight paint and flexible strips on the windows.

– Design with reduced thermal bridges. The reduction of thermal bridges has been prioritised in the construction of the building through the appropriate choice of materials.

The airtightness of the building is determined by the differential pressure test (BlowerDoor test). The Enerphit certificate requires an airtightness level of n = 1.0/air change per hour. During the refurbishment of this laboratory, three BlowerDoor tests were carried out to check the progress of the work and a value of 2.1 air changes per hour was achieved.

This is three times better than the values established by the Technical Building Code, which is 6 renovations per hour. Therefore, it is a success in the design and execution of the works.

Reuse, reduction and recycling. The three R’s have been applied in this project.

Those elements of the furniture that could be reused have been restored and given a new use in this innovative and renovated laboratory. Under this same premise, it was decided to maintain the terrazzo floor, polishing it to give it an impeccable finish and avoiding the generation of waste that would be involved in removing and replacing it.

This refurbishment not only provides a more comfortable and healthy space for students, but also sets a model to follow in terms of sustainability and energy efficiency in the academic environment.

More info:

https://energiehaus.es/wp-content/uploads/2023/07/Guia_de_certificacion_de_edificios_PHI_ES.pdf